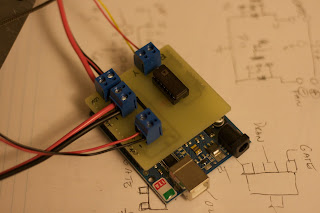

Since the circuit was so simple I designed this in Solidworks rather than a schematic CAD program. The circuit consists of an AD595 to convert the temperature from a type K thermocouple, and a pair of NIF5003 FET's to control power to the heater resistor, and the fan for cooling the heater heat sink. I milled this board using a combination of 1/16" and 1/32" end mills, cutting .003" thick. It's key to make sure that the board is very flat when milling, as errors of a couple of thou will easily be reflected in a cut that shallow. I faced a small metal plate in the vise first, to make sure it was as flat as the mill could make it before double stick taping the board down. I am quite pleased with the result, I'll have to make more boards like this in the future.

Here is the board on top of the Ardunio board I have. You can see the AD595 on top in a socket (no sense committing a $20 chip until you know the circuit works). The two FET's are hidden on the bottom of the board, as they are surface mount, and I only felt like doing a single sided board.

I whipped up some really rough test code to see if I could get some temperature control out of this thing. I'm happy to report that it seems to work well so far. I should really get another thermocouple to confirm temp accuracy. You can also see the PTFE insulator parts around the heater block in the second picture. There are still some minor mechanical things to finish before I can start pumping plastic through it, with any luck I can get that happening later this week.

No comments:

Post a Comment